In the realm of quality management, two contrasting philosophies often stand out: Philip Crosby’s Zero Defects Attitude (ZDA) and Joseph Juran’s Statistical Process Control (SPC). These approaches offer distinct perspectives on how to manage and achieve quality within organizations. Let’s explore the strengths of Crosby’s Zero Defects approach in contrast to the methodology of Statistical Process Control, especially from a biblical perspective emphasizing stewardship and accountability.

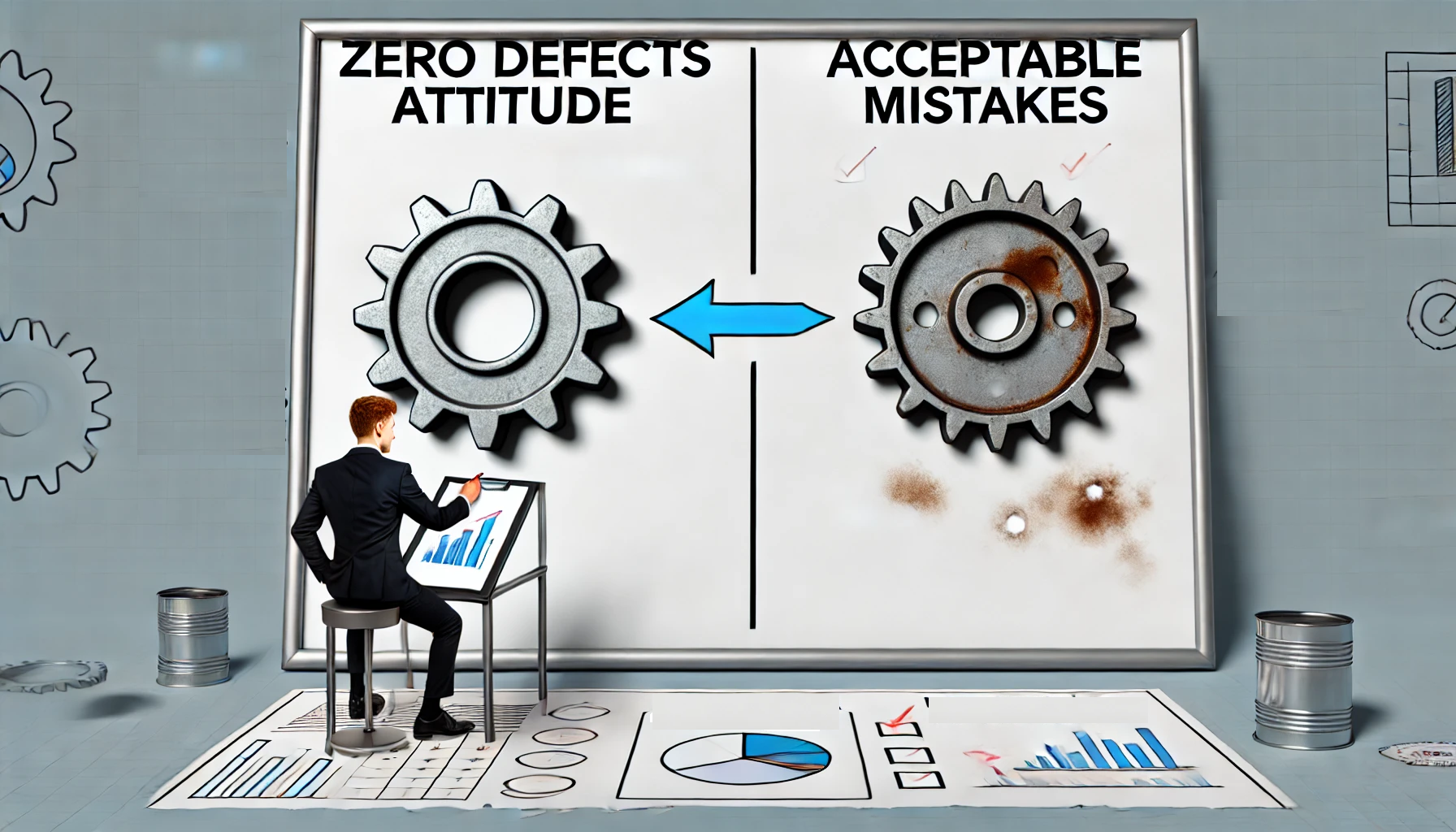

Philip Crosby’s Zero Defects philosophy asserts that quality should be measured by the standard of zero defects. This stringent approach advocates for preventing errors before they occur, rather than accepting them as inevitable outcomes of complex processes. Crosby argued that striving for perfection not only reduces costs associated with defects but also enhances customer satisfaction and organizational reputation. From a biblical standpoint, this philosophy resonates with the call to offer our best in all endeavors, reflecting our commitment to excellence and honoring God through our work.

On the other hand, Statistical Process Control, as advocated by Joseph Juran, focuses on managing variability and maintaining processes within statistical limits. SPC uses statistical methods to monitor and control processes, allowing for a certain level of variation that is considered statistically acceptable. This approach acknowledges that achieving zero defects in all circumstances may be impractical or economically unfeasible. However, it also implies a level of tolerance towards errors that, while statistically manageable, may still impact customer satisfaction and organizational performance. In other words, it there are “Acceptable” Mistakes allowed in the model.

While SPC offers a practical framework for managing variability in production processes, its acceptance of defects—even at a statistically low rate—can be problematic in real-world applications. The limitation of SPC is evident when defects, even those within accepted statistical limits, have serious real-world consequences. For instance, in critical industries like automotive or healthcare, where safety and efficacy are paramount, any level of defects accepted by statistical norms could lead to significant adverse outcomes, such as equipment failures or health risks. In these cases, the statistical acceptability of defects does not align with ethical or customer expectations, highlighting a critical shortfall of the SPC approach when human safety is at stake.

While Statistical Process Control provides valuable tools for managing process variability, Crosby’s Zero Defects philosophy better encapsulates a striving towards biblical excellence and expectations of managing your talents well. It promotes a culture that not only aims for the highest standards but also aligns with ethical and moral values that treat every defect as significant. In industries where the quality is critical, adopting a zero defects mindset may provide the best path towards ensuring safety, efficacy, and customer satisfaction, reflecting a commitment to stewardship and integrity that resonates with Christian values.

Comments are closed